Dynamic Perception Stage One User Guide

The Stage One Slider/Dolly is a multi-function camera slider designed for shooting video and timelapse with dSLR cameras, either manually or motorized. With a focus on light-weight, ease of transport, and extensibility, the Stage One is an all-around performer for artists in the field.

This user manual will guide you through the assembly, setup, use, and maintenance of the Stage One slider.

Warnings

- The Stage One Slider contains small parts and should be kept out of the reach of children

- Care should be utilized when assembling the Stage One, several pinch points may cause injury to fingers or hands. Pay close attention when attaching mid-span supports, tubes, and belt clips to ensure that fingers and hands are clear of any pinch points.

- Always ensure that the path of the camera when on the slider is free from any obstacles. Do not rely on friction brakes, electronics, limit switches, or due attention to prevent damage to camera or other equipment.

- Do not use slider in environments where there is a risk of electrical shock or lightning. The Stage One is made out of aluminum which is highly conductive to electricity. Injury or death may occur if the slider is struck by lightning or comes into contact with an electrical charge.

- Keep all body parts clear of the path of the cart at all times. Serious injury can occur from a weighted cart. Do not rely on friction brakes, electronics, limit switches, or due attention to prevent harm.

- Always ensure that the slider is properly supported before use. Do not use the slider leaning against an object as the only form of support.

Maintenance and Care

- Always ensure that Stage One parts are clean and dry before storage, assembly, or transport

- Keep rubber caps on both ends of extension tubes when in storage and transport

- Do not attempt to thread any parts together if threads are dirty or damaged

- Do not store for extended periods of time with belt installed and tensioned

- Wipe down rails with a clean, soft cloth before using

- For long life, avoid use in rain or very dusty environments

- Bearings are sealed and are not user-serviceable, do not attempt to lubricate them

- Clean components with damp cloth and mild soap and dry completely. Do not use solvents or cleaning products with abrasives to clean the Stage One or any part.

- Ensure that cart wheels are clean and free of debris before assembly

Assembly

1. Connect Extension Tubes

Remove the rubber end caps from each extension tube. Holding one tube in each hand, thread the male threaded tube end into the female threaded tube end. Take care to ensure that threads are started correctly, they should very easily thread into each other. Cross-threading the tubes or forcing them together when they appear to not want to connect can result in permanent damage to the threads. Assemble two rails of equal length for the slider.

2. Thread Rails Into Female End Cap

Holding the female end cap (the end without the knobs) with one hand, use the other free hand to thread the male end of each rail into the end cap. Repeat for each rail, taking due caution to avoid cross-threading or attempting to force the threads to seat. Each rail should thread in easily with no force.

3. Slide Cart Onto Rails

If you using only one extension set (for a 21" travel length), you must now slide the cart onto the rails before attaching the male end cap. If you are using two or more extension sets, you may instead wait until optional Step 5 below.

Before installing the cart, ensure that the friction brakes are fully loosened, and that the friction brake knobs are at least 1/2" out from the cart uprights.

Ensure that all wheels are correctly located on the rails.

For most uses, the cart should be installed such that the top plate is on the same side of the rails as the belt clips.

4. Attach Male End Cap

You may now attach the male end cap by lining up the female ends of the rails with the threaded posts inside of the end cap, and turning the knobs evenly. Don't attempt to tighten one knob down fully before moving to the next. Each knob must be tightened or loosened evenly. If one knob fails to turn, reverse whatever you just did on the previous knob slightly to free it. Ensure that the knobs are complete tight before use, and that the belt clips on both end caps are on the same side of the rails.

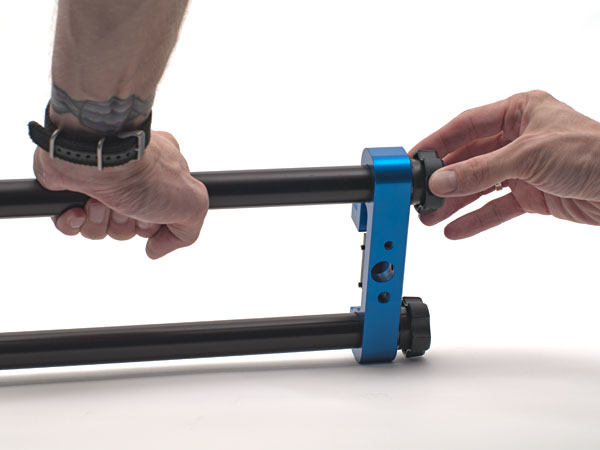

5. (Optional) Compress Rails to Install Cart

When using two or more extension sets, you may find it easier to install the cart after having fully assembled the rails, by gripping both sides of the rails at the center of the slider, compressing with your hands and then slipping the cart on, one side at a time. With practice, most users will find this the easiest way to install the cart in the field.

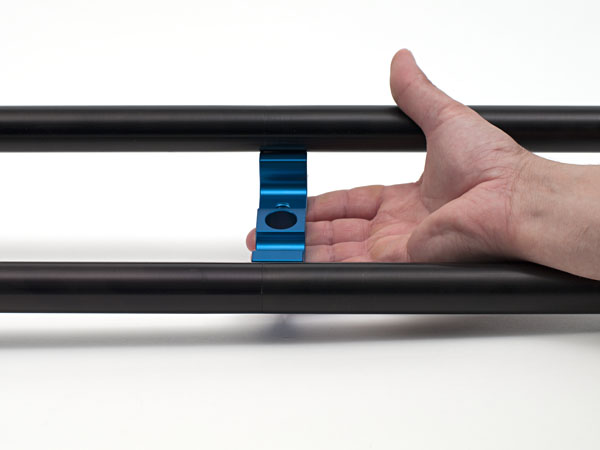

6. Snap In Mid-Span Supports

For best results, one mid-span support should be used at every rail tube intersection. To install the mid-span supports, bring the mid-span support up from below the rails, and press upwards until it snaps firmly into place. Be very careful to keep your hands and fingers clear of the intersections between the mid-span support and the rails to prevent injury. Ensure that the cart is clear of the area you are installing the mid-span support, otherwise it may be difficult to snap into position.

To disassemble, simple repeat these steps in reverse, pulling downwards on the mid-span supports to release them.

Packaging for Travel

- To pack the Stage One for transport, disassemble the unit completely according to the assembly instructions. The following tips will help to ensure a long life for your slider, and aid in preventing damage during transport:

- Always pack the rail tubes separate from the cart, endcaps, and mid-span supports to prevent scratching and gouging of the rails

- Always replace the rubber covers over the end of the rail tubes to prevent damage to the threads, and to keep them clean

- Ensure that belt clip bolts are tightly attached before packing, to prevent loss of belt clips during transport

- Ensure that friction brakes are fully threaded into the cart before packing, to prevent loss of friction brakes during transport

- Keep rail tubes in a package with a firm exterior to prevent bending of the tubes

- Never travel with rail extensions connected together to prevent bending of the tubes or damage to the threaded couplers

- For best results, always transport the Stage One in its original packaging

Manual Slider Operation

The basic Stage One system can operate as a standard, hand-pushed slider for smooth video shooting. The included friction brakes add additional friction to make it easier to make smooth starts and stops when pushing the camera by hand. It is not required to purchase a DC Motor Upgrade Kit to use the Stage One as a manual slider.

If you have installed a DC Motor Upgrade Kit, always completely remove the belt before attempting to use as a manual slider!

To use the Stage One as a manual slider, first attach your preferred camera mounting solution, such as a ballhead, to the cart using the provided hardware. After having mounted the cart to the slider, now mount your camera and adjust the position to the desired framing. Adjust the friction to the desired level by tightening the friction brake knob on each side of the cart equally. Note that the friction brakes will not completely stop the cart from moving under load. The heavier the camera, the more friction you should apply for the best results. Using your hand, push the cart from the desired starting point to the desired end point.

Motorized Slider Operation

Using a DC Motor Upgrade Kit, you can create beautiful timelapse videos with the Stage One and the MX2 Motion Controller.

DC Motor Upgrade Kit Installation

The following instructions will guide you through installing the DC Motor Upgrade Kit on your Stage One.

1. Locate and Count all Components

1x. Hex Tool

1x. Motor with installed bolts, spacers, and bolt retainers

2x. Idler assemblies

1x. Pulley

2. Install Motor Onto Cart Plate

a. Place the motor on the top plate of the cart, aligning the bolts with the bolt holes and the shaft with the large shaft through-hole.

b. Using the provided hex tool, tighten down the bolts by starting at one corner, then moving to the opposite corner, until all four bolts have been started. Do not tighten down any bolts fully until the all four bolts have been started.

3. Remove Cart Upright

a. Turn cart over and using the provided hex tool, remove the upright nearest the motor. Note: you may find it easiest to remove the upper wheels from the upright first.

4. Install Pulley Onto Motor Shaft

a. Slide the pulley onto the shaft, with the hub facing towards the plate. Space the hub face approximately 1/8" from the bottom of the cart plate, ensuring that one of the set-screws is at the center of the flat on the shaft.

Note: the cardboard card from the hex tool can be used as a shim for spacing the pulley, simply lay it flat against the plate bottom and let the pulley rest on it.

b. Using the smallest hex tool, tighten the set-screw at the center of the shaft flat

c. Using the same hex tool, tighten the set-screw at the side of the shaft

5. Assemble and Install Idlers

a. Locate the mounting hole for each idler near the motor shaft

b. Start each idler bolt into a mounting hole and tighten with the included hex screw

6. Re-Install Upright

a. Place the upright back on the bottom of the cart, and use the supplied hex tool to re-install the upright. Make sure to tighten down the bolts as tight as you can. If you removed the wheels, re-install them after attaching the upright to the cart.

Preparing the Slider for Motorized Operation

To prepare the Stage One for Motorized Operation, you will need to ensure that the cart is correctly installed, and then attach the belt.

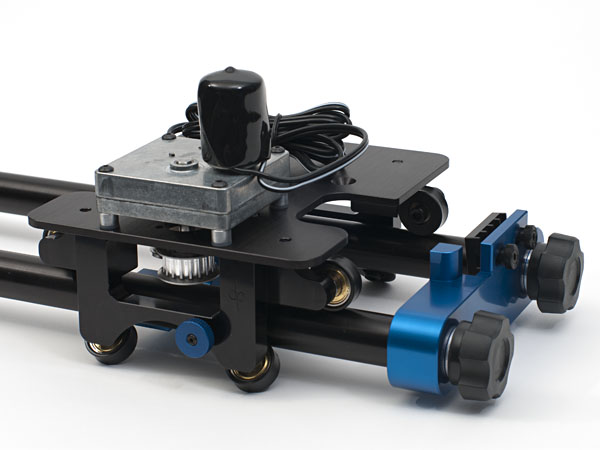

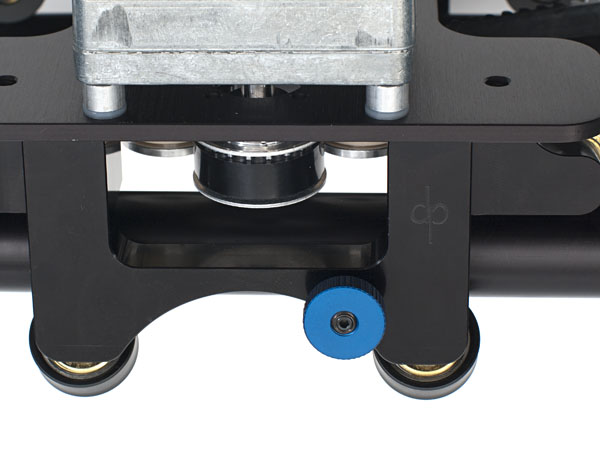

The cart must be oriented such that motor is on the same side of the rail as the belt guides. The following photograph illustrates the correct orientation:

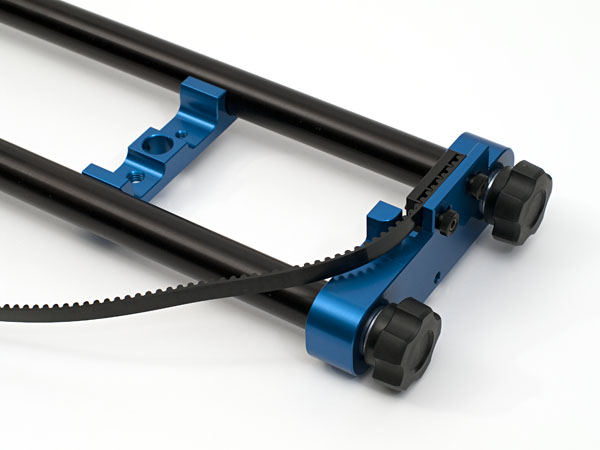

After installing the cart, you will now need to attach the belt. Starting at one end, loosen the belt clip and install one end of the belt into the clip such that the belt teeth and the clip teeth meet each other. Slide the belt clip so that it is closest to the belt guide, and then tighten the clip bolts tightly with your fingers. Guide the belt out and around the belt guide, and then to the cart.

Feed the free end of the belt around the nearest idler and pull all of the slack belt through. Guide the loose end of the belt through the space between the idler and the pulley, and then around the pulley. Now, feed the belt fully around the pulley, and behind the second idler. With your free hand, push the cart away from the end of the slider where the belt is already clipped in to, to tension the belt on that side of the cart.

Prepare the remaining belt clip by loosening it, and sliding it in closest to the belt guide. Keeping some tension on the belt, guide it around the outside of the last belt guide, and slide it into the belt clip. Tighten the belt clip approximately half way, and with one hand, push the clip away from the guide with your thumb to tension the belt, and then tighten the clip with your other hand. If the belt has gained some slack on the opposite side of the cart during this process, you may loosen that belt clip slightly and push it away from the belt guide before tightening it again to remove this slack.

The belt should be fairly taught, but not extremely so, during operation. On longer runs, some slack will be present in the belt.

For those on a budget, it is recommended to use one length belt for your longest setup, rather than cutting it to different lengths, and let the extra belt hang off of the end of the track, or secure it with a rubber band.

Supporting the Stage One

ailure to properly support the Stage One may result in damage to the Stage One, your equipment, or nearby persons. Always properly support the Stage One when in use.

The following rules should always be followed when using the Stage One:

- Never support the Stage One by leaning it against another object, the load may shift during the shoot and cause the slider to topple over. Always lash it to any item it is leaning against with a cord, rope, or other device to secure it in place.

- When using century mounts, such as with light stands, always tighten down the included C-Stand mount bolts fully before loading the camera on the slider

- When using tripods, legs, or other support devices, ensure that they are fully tightened down before use

- Make sure that all support components are placed with good footing and may not lose their stance or topple over

At a minimum, a support of some sort should be provided for every four feet (or two extension sets) of free travel.

Using Tripods for Support

Both end caps and the mid-span supports have standard 1/4-20 and 3/8-16 threaded holes. These mount points can be used to attach quick release plates, or tripod legs directly. Please note that as these holes are to either side on the mid-span supports, it is recommended to alternate the orientation of each mid-span such that your tripods are not all offset to the same side.

Using Light Stands for Support

Each end cap and mid-span support has a central mount point for use with Century stand style mounts. As each mount point is centered, you do not need to alternate the orientation of the mid-span supports. Always secure the mount points with an appropriate bolt.

Quick Table-Top Support

If you are using the Stage One in a manual slider configuration, you can easily use it up to four feet long on a table top without additional support by installing the cart upside down on the rails, such that the belt clips are facing down, away from the cart. In this way, you may simply place the slider on a table top, or other level surface without additional supports.

Getting Support

We at ElysiaVisuals want to support our customers to the fullest. Please contact us for support if you have any questions.

related products - Related Products

- Log in to post comments